The selection of a High Quality Aluminum Window Manufacturer is a critical decision in modern construction and renovation, significantly impacting a building's energy efficiency, structural integrity, and aesthetic appeal. Aluminum windows, prized for their strength, light weight, and minimal maintenance, have become a staple in residential and commercial architecture worldwide. However, the market offers a vast spectrum of products, and discerning the difference between a high-performing system and a substandard one requires a clear understanding of the benchmarks for quality. This article explores the defining characteristics of a superior aluminum window manufacturer, contrasting premium products with lower-tier alternatives, and examines how a commitment to rigorous standards translates into long-term value for a project.

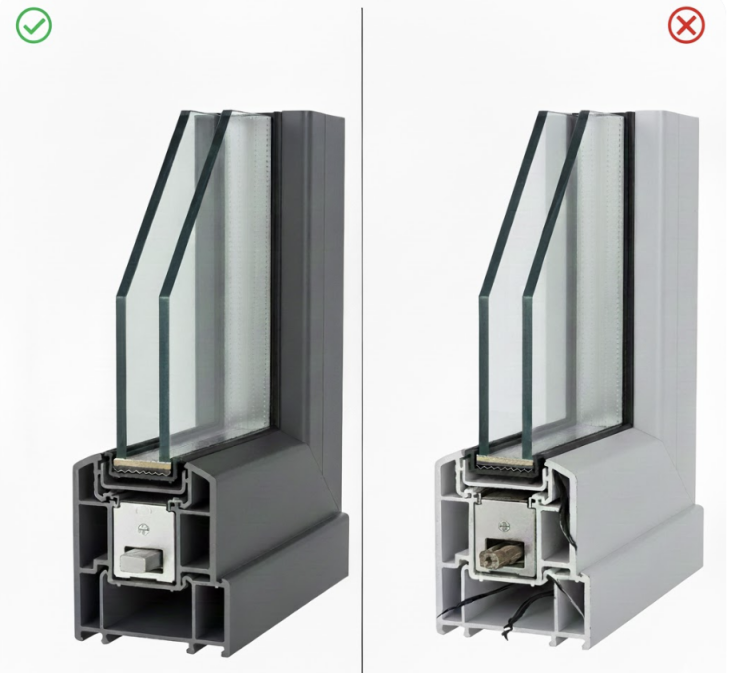

A foundational difference between manufacturers lies in their approach to raw materials and production processes. High-quality aluminum windows begin with certified, often virgin-grade, aluminum alloys that offer optimal strength and corrosion resistance. A crucial technical feature is the thermal break, a non-metallic material inserted into the window frame's cavity. This design dramatically reduces thermal conductivity, a defining trait of true high-performance windows. Manufacturers focused on quality meticulously engineer these breaks to ensure maximum insulation, preventing heat transfer and mitigating condensation—key factors in maximizing energy efficiency. In contrast, lesser-quality manufacturers may use thinner aluminum profiles, omit the thermal break, or use inferior, less durable breaking materials, leading to poor insulation and increased energy costs over the building's lifespan.

The manufacturing environment is another critical differentiator. Top-tier manufacturers utilize precision CNC equipment and streamlined production lines to ensure every component, from the corner joint to the drainage system, is fabricated to tight tolerances. This precision is essential for the window's operational performance, ensuring smooth opening and closing, airtight seals, and effective water resistance. For example, a decade of specialized production capability, like that demonstrated by Xiamen KDSBUILDING Material Co., Ltd., allows a manufacturer to refine these complex processes, achieving an annual output of systems that consistently meet exacting standards. Subpar manufacturing often results in loosely fitting components, uneven seals, and premature wear, requiring costly repairs or replacements years down the line.

While the aluminum frame is vital, a high-quality window is a cohesive system where every element contributes to the overall performance. The glass unit is arguably the most complex component. Leading manufacturers offer a range of glazing options, including double or triple-pane units filled with inert gases like Argon, and incorporate Low-E (low-emissivity) coatings to control solar heat gain and thermal loss. The quality of the sealing system, often using EPDM gaskets, is also paramount. A tight, continuous seal ensures the window is airtight and watertight, preventing drafts and moisture intrusion—a common failing in inferior windows where seals can crack, shrink, or lose elasticity rapidly.

Hardware quality is another non-negotiable standard. Premium windows utilize robust, multi-point locking mechanisms, durable hinges, and specialized operating mechanisms that are tested for tens of thousands of cycles. These components are often made from corrosion-resistant materials like stainless steel. When selecting a product, the difference between quality and compromise is evident in the feel of the window—smooth operation, secure locking, and a sense of structural solidity. Conversely, cheap, low-grade hardware on budget windows is a primary point of failure, often snapping or seizing up, which compromises both security and functionality.

Perhaps the most objective measure distinguishing a high-quality aluminum window manufacturer is their commitment to attaining and maintaining rigorous international certifications. These certifications are not merely marketing tools; they are the result of independent, accredited testing that verifies a product's performance under specific conditions, addressing critical metrics such as:

Thermal Performance: Measured by U-factor and Solar Heat Gain Coefficient (SHGC), standardized by bodies like NFRC (National Fenestration Rating Council).

Structural Integrity and Air/Water Resistance: Determined by test standards from organizations like AAMA (American Architectural Manufacturers Association) and AS 2047 (Australian Standard).

Safety and Compliance: Such as CE marking for European conformity and UL listings for fire safety.

A manufacturer whose product range meets major global standards like NFRC, AAMA, CE, UL, and AS 2047, as Xiamen KDSBUILDING has achieved, demonstrates an unwavering commitment to meeting a global minimum for performance and safety. This compliance is particularly crucial for projects intending to export or requiring specific regional approvals, providing architects, builders, and end-users with a reliable assurance of quality. Failure to meet these standards not only poses risks in performance but can also lead to regulatory non-compliance, jeopardizing the entire project.

The distinction of a high-quality manufacturer extends beyond the factory floor and into their professional support structure. Projects involving high-end window and door systems, such as aluminum glass curtain walls and complex window-door composites, demand sophisticated engineering support. A superior manufacturer offers more than just a product; they provide the engineering expertise needed for accurate project quotation, custom system design, and comprehensive order follow-up. This support ensures that the chosen system is correctly specified for the local climate, wind loads, and energy codes.

With over 15 years of exporting experience and a specialized foreign trade department, a manufacturer can navigate the complexities of international logistics and diverse project requirements, from the stringent energy codes of the USA and Canada to the cyclone-rated requirements of Australia and the Caribbean. This global application is evident in projects across diverse markets, including the UK, Norway, South Africa, and the Philippines, where the manufacturer’s commitment to superior craftsmanship and stable performance is demonstrated through their installed systems. The ability to supply a comprehensive product range—including aluminum, PVC/uPVC, solid wood, aluminum-wood composite, steel, and fire rated windows and doors—further solidifies their role as a trusted partner capable of handling mixed-material and high-complexity building envelopes.

The initial allure of lower-priced, lower-quality windows often fades rapidly when considering the total cost of ownership. Inferior products necessitate higher energy consumption, leading to increased utility bills. They are prone to failure in hardware, seals, and structure, incurring frequent and expensive maintenance costs. Furthermore, they can compromise the interior environment through drafts, leaks, and noise transmission, ultimately diminishing the value and comfort of the property.

In contrast, investing in systems from a High Quality Aluminum Window Manufacturer delivers value over decades. Their commitment to precise manufacturing, top-tier components, and verifiable global certifications results in:

Exceptional Energy Efficiency: Reducing operating costs.

Enhanced Durability: Ensuring long-term structural integrity and minimal maintenance.

Superior Performance: Providing reliable resistance to air, water, and noise.

Professional Support: Offering peace of mind from specification to installation.

Ultimately, choosing a manufacturer that operates at the highest echelons of global standards—a partner like Xiamen KDSBUILDING—is an investment in the long-term performance, safety, and architectural success of any building project.

For more information on high-quality aluminum window and door systems, please visit: https://www.kdsbuilding.com/